Overview

This section will cover the use of the alarm management control in the Alarms tab. This control in combination with the additional alarm controls allow operators to respond to or delegate alarms as required.

Prerequisites

- Completion of Understanding Alarm Management and Procedures - Part 2.

The Alarm Management Tab

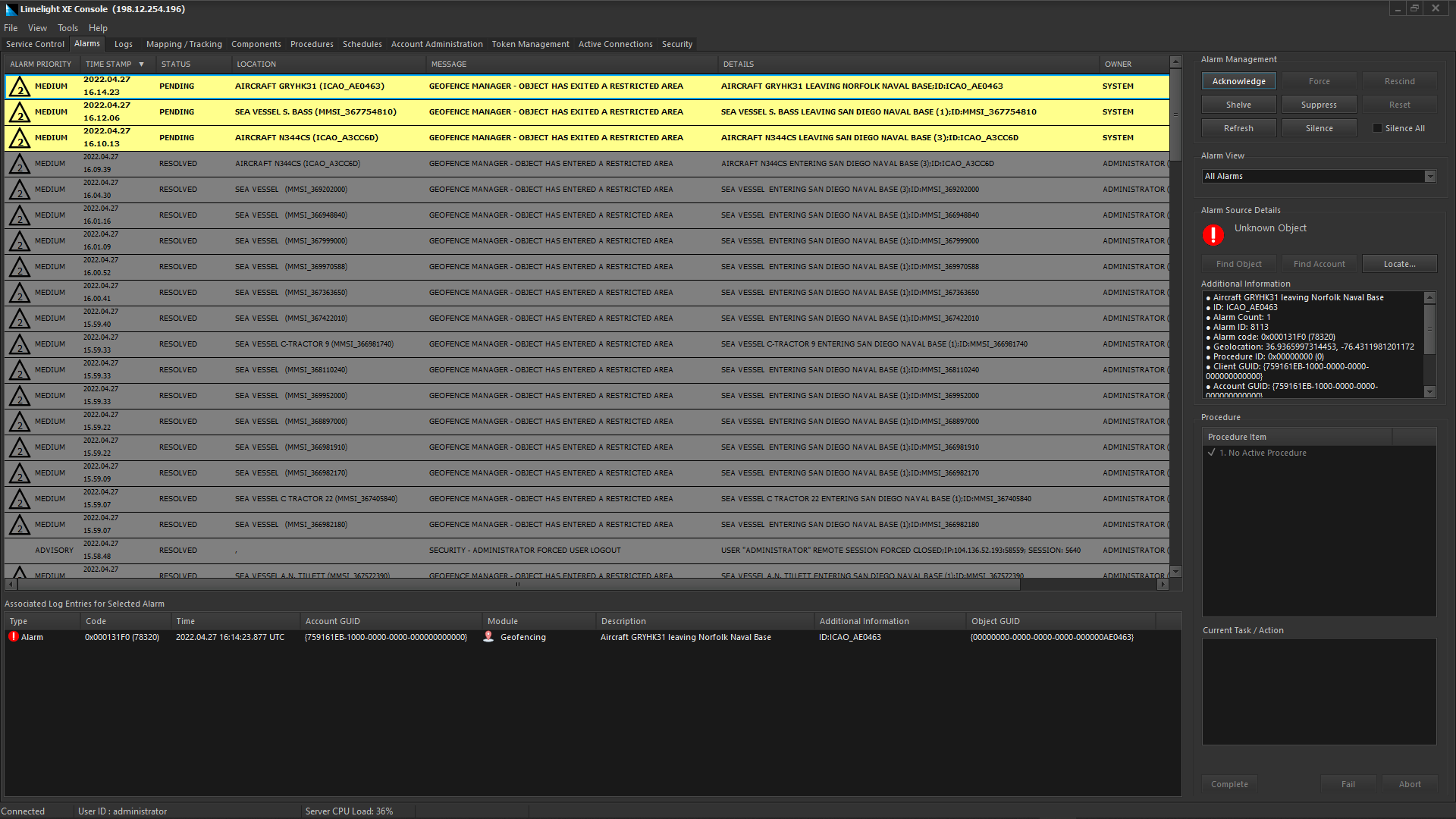

The Alarms tab in the Limelight XE console allows operators to respond to and handle alarm conditions asserted by the system. Alarms can come from many sources - internally (e.g. core functions such as security) or externally (e.g. a PLC monitoring temperature or flow rate). Alarms are tightly connected to the logging system - in fact they're triggered by log entries that meet a certain criteria. Since all changes in the system are logged to the master log data base, this is a perfect point in the information flow to extract alarms.

Below is a snap shot of typical alarm conditions - this view shows the alarm, who owns it, its status and priority. Alarms can be sorted by clicking the column header at the top of the alarm view which can allow operators to view the most important or most recent alarms. Each alarm item is tied to the log events (both recent and previous) that caused them - they are shown in the list view below the alarm view.

In the example below, you can see a recurring error between a Modbus TCP PLC and the driver... in every case except the two pending alarms at the top, the operator has chosen to acknowledge the alarm. In this case it is possible a communications link issue is the cause and the operator can call technicians to run some diagnostics to find the error. It may also be caused by too frequent polling of the PLC by the driver. In either case, the alarms indicate that an issue exists that requires attention.

The most recent entry (top line) was a notification that the operator had just logged in and their startup script had been run. If the operator does not acknowledge this particular alarm, a timeout was set in the procedure to simply resolve the alarm automatically. This feature can be very useful to prevent alarm flooding... lower level alarms that don't necessarily require attention can be configured to "time-out" to the RESOLVED state. The alarm manager can also be configured to automatically escalate an item's priority if not acknowledged in time. This is a global setting and can be enabled by setting the Alarm Escalation Period (in seconds) to anything higher than zero (0). So if an alarm timeout is set to zero (0), it will never time out (automatically), but rather be escalated and reintroduced into the alarm pool if not acknowledged within the escalation period. A good value for this feature if used would be in the 120-360 second range allowing an operator time to handle the alarm under normal circumstances.

Operator alarms management tab showing various alarms